Designing the Main Structure

Nisarg Thakrar

February 202

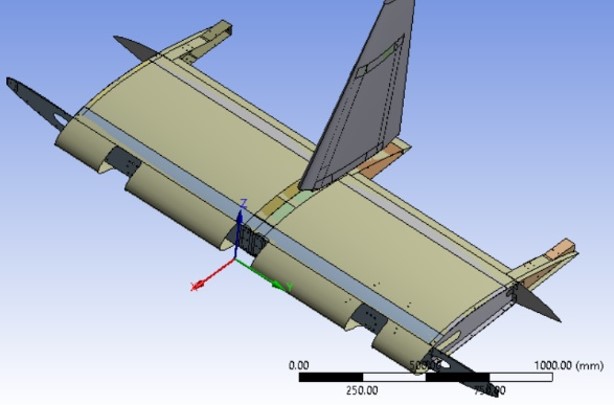

The main structure has been a key driver in helping us to achieve our dream of designing one of the first compact vertical take-off and landing (VTOL) aircraft.

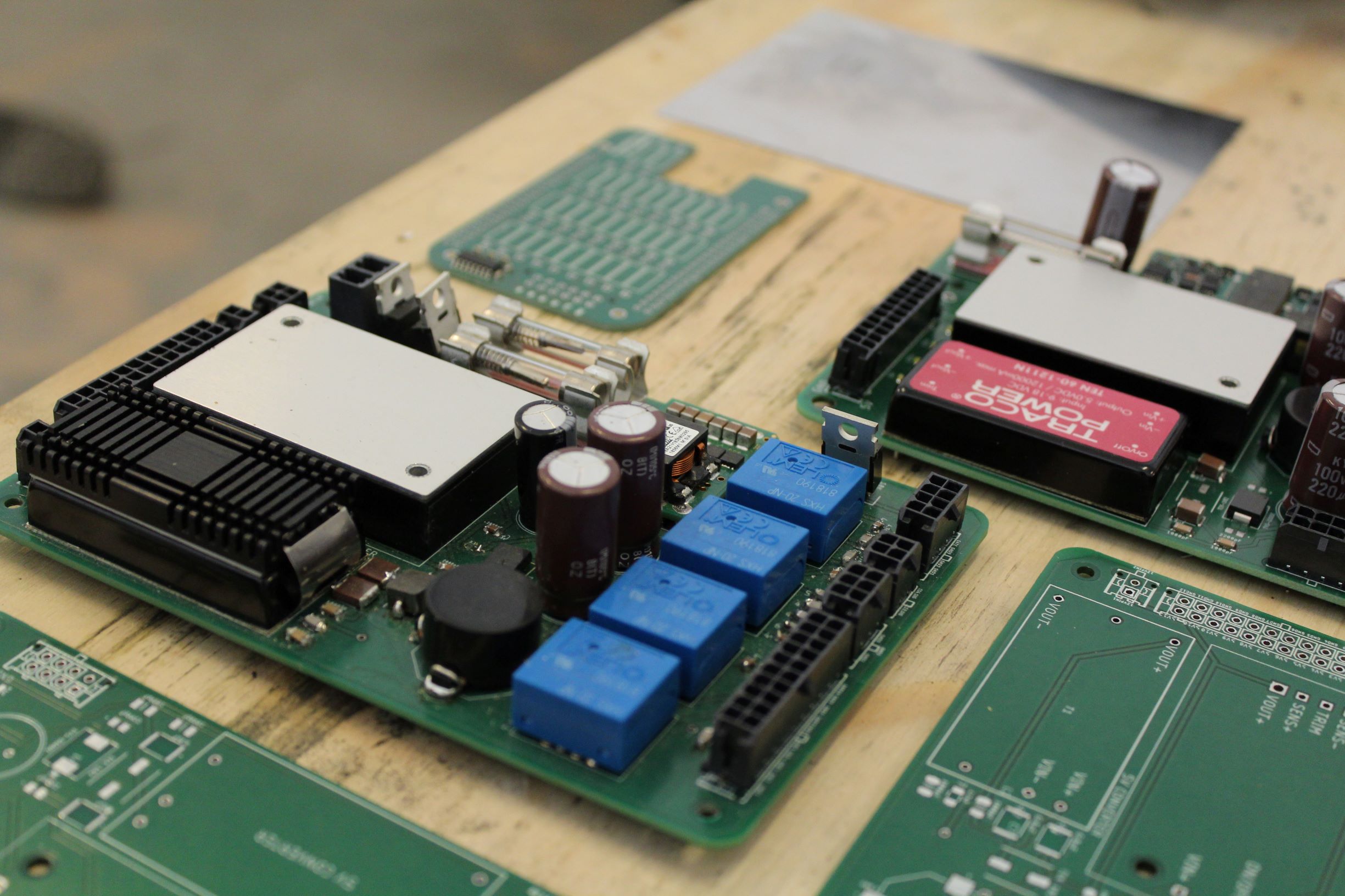

The structure has been able to support the surfaces needed for aerodynamic performance, the lightness necessary to achieve flight on battery power, and the spaces and mountings required to enable autonomous function and maneuverability. It stands to be one of the most important systems as it takes the theories of VTOL flight on paper and allows it to be implemented into a real, usable structure enabling personal flight.

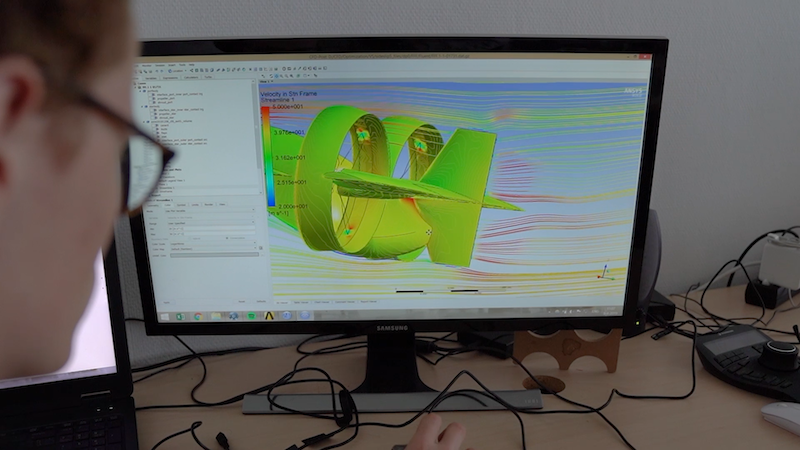

The main importance of the structure is that it supports all other subsystems required to manage flight, and as such, it was a constant battle to find a viable method to support every other subsystem requirement. One of the key trade-offs was to find a balance between driver comfort, meeting global size restrictions, and fitting a viable, aerodynamically efficient driver pod with suitable integrity. Aerodynamic performance was favored above all else to ensure efficiency in flight, as well as reduced battery load. As a result a complex surface had to be designed which was able to comfortably support a driver, and integrity had to be maintained through novel means.

The challenges didn’t remain at the design phase but in fact continued into the production phase. When staring at a model in a computer-aided design (CAD) program, you sometimes forget how hard it is to get your hand into a specific place to access a bolt. This was one of greatest challenges we faced when we started getting into the assembly phase. We overcame this on the spot, using practicality to tweak designs, remove sections, or add parts that would aid assembly and thus ensure maximum efficiency in system maintenance during testing.

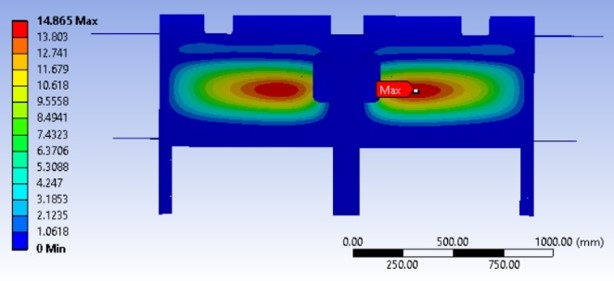

When it came to testing, that was the first time all systems were working concurrently together. This is where some performance concerns came to light, specifically the vibration of the driver pod during flight. As such, modifications were made to increase stiffness and support so that the amplitude of vibrations could be reduced.

This whole period, the best times have been the times leading up to the big submissions, when the team comes together to support each other, help each other perform better, and develop some great ideas to secure the win. The team comradery throughout the whole period has made this project one of the most enjoyable ones I’ve been part of, and has been one of the key reasons for our success so far. The only sad thing was when I couldn’t spend all my time working on this great project, as I had commitments with my university degree that also needed to be met. Beyond that, participating in this project has left me with no regrets.

Now we are approaching the finishing stages. Fortunately from our side, there’s not many modifications to be made, but we do travel to the US with a lot of spares so we can act quick in the event of any form of failure. We have an exciting month ahead, with many challenges still to overcome, but we keep a positive outlook.